Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

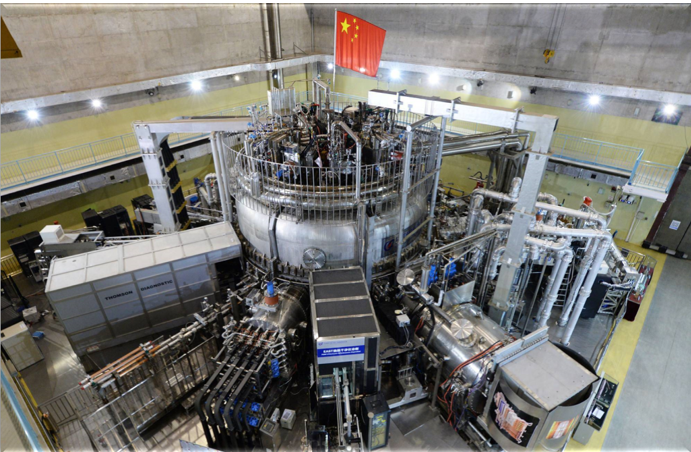

The Institute of Plasma, Chinese Academy of Sciences, is an important base for research on thermonuclear fusion in China. It has successively built conventional magnets such as the Tokamak HT-6B and HT-6M, the first circular cross-section superconducting Tokamak nuclear fusion experimental device in China, the "Hefei Super Ring" (HT-7), and the world's first non circular cross-section fully superconducting Tokamak nuclear fusion experimental device, the "Eastern Super Ring" (EAST). It has achieved a series of internationally advanced or unique results in physical experiments, Received 2 National Science and Technology Progress Awards and multiple important national awards.

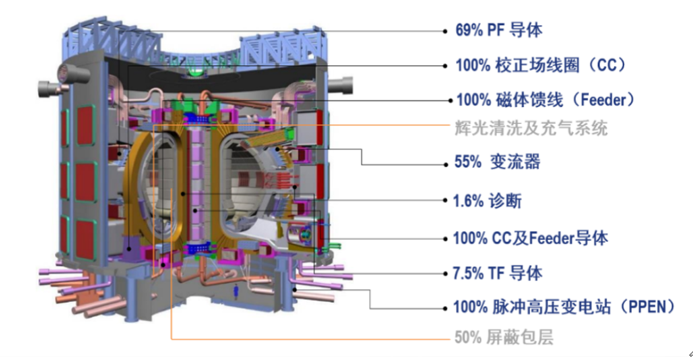

Tokamak is a circular container that utilizes magnetic constraints to achieve controlled nuclear fusion. Its name Tokamak comes from toroidal, vacuum chamber, magnet, and coil. The center of the Tokamak is a circular vacuum chamber with a coil wrapped around it. When energized, a huge spiral magnetic field is generated inside the Tokamak, heating the plasma to a high temperature to achieve nuclear fusion.

The physical problems of plasma stability, transport, and wall equilibrium under steady-state, high parameter, and high constraint conditions all need to meet the design requirements in all aspects of parameters. The installation of the main structure and the accuracy of coil winding determine the strength and stability of the magnetic field.

Figure 1: Schematic diagram of Tokamak and its structure

High field Rutherford cable MRI conductor preprocessing work

Conductor installation → conductor release → conductor straightening (straightness measurement and cross-sectional dimension measurement) → ultrasonic cleaning → sandblasting and cleaning (flatness measurement) → bending and winding forming (forming radius measurement and cross-sectional dimension measurement).

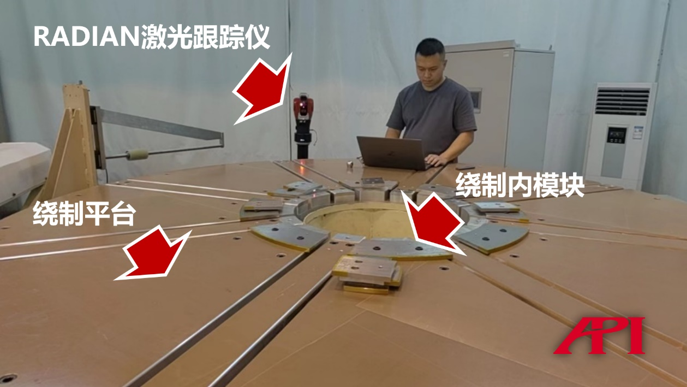

After the conductor is completed and put online, it is necessary to calibrate the feed accuracy of the production line equipment and measure the installation of the winding mold. This time, the main solution is to install, calibrate, and measure the winding mold.

Measure and implement:

-Adjust and calibrate the flatness of the winding platform tabletop before installation (please refer to Figure 3);

-Install, adjust and inspect the winding internal module (please refer to Figure 4);

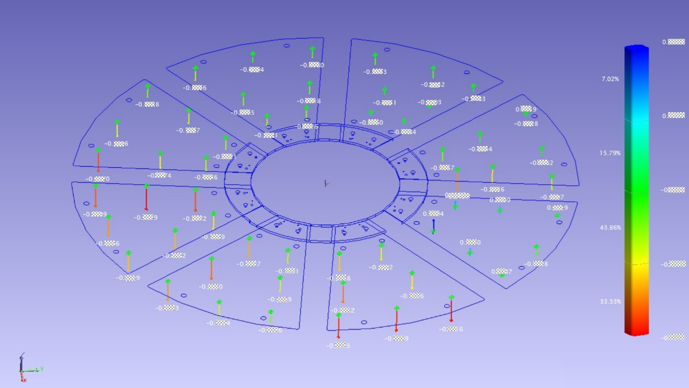

-Correct the flatness of the winding coil (refer to Figure 5) and the deviation between the outer ring and the theoretical model (refer to Figure 6).

Please refer to the following on-site documentary images and data reports:

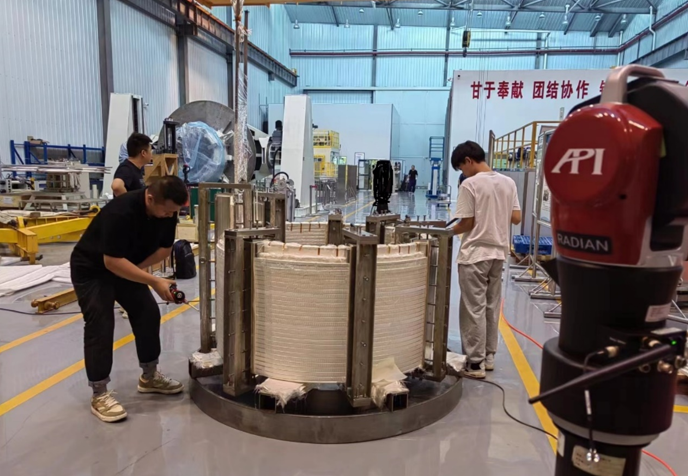

Figure 2: Calibration and Measurement Site for Winding Mold Installation

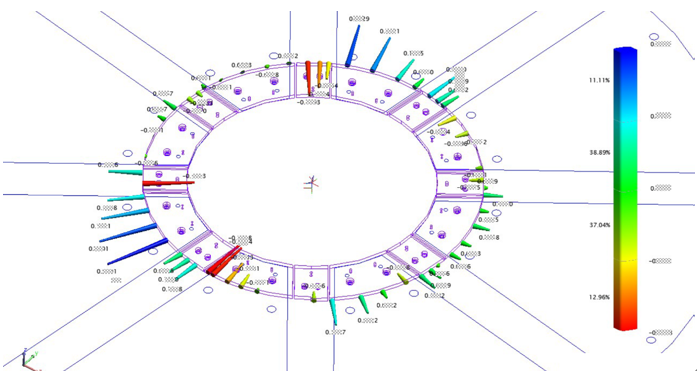

Figure 3: Report on flatness measurement data of the winding platform tabletop

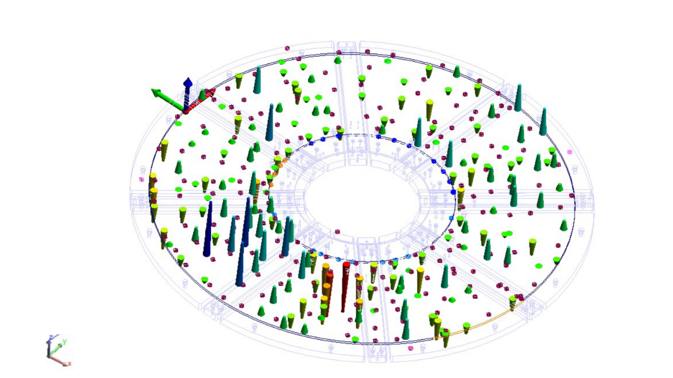

Figure 4: Measurement and data for installation and adjustment of winding internal modules

Figure 5: Report on flatness measurement data of wound coils

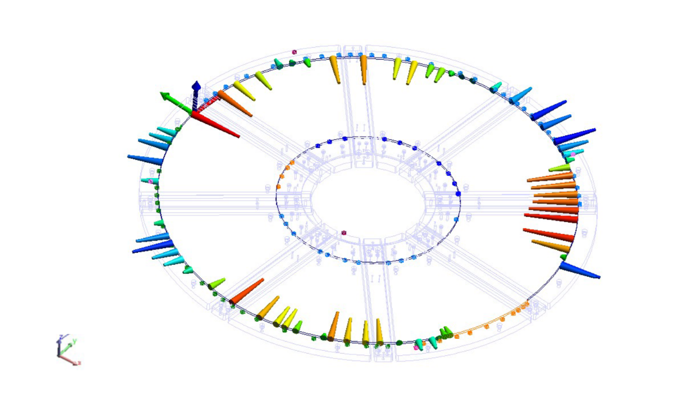

Figure 6: Deviation measurement data report of the outer circle theoretical model

Figure 7: Fusion coil measurement site

And the built-in Autolock automatic light receiving function of Radian Plus automatically searches and locks the target ball in case of light interruption, and conducts real-time data comparison and analysis at a measurement frequency of 1000 points per second according to requirements. The Autolock intelligent camera can have a field of view angle of up to 30 °, and can quickly and automatically complete measurements at any measurement point on the experimental platform and adjust them in real-time. During the repeated debugging and installation process, the software can automatically complete data collection and analysis calculations.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.