Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

On the measurement of the main and secondary reflector surfaces of antennas

For modern aviation, aerospace, and communication processes in vehicles and ships, radar antennas play a crucial role. During the operation of the antenna, due to factors such as gravity, wind load, and temperature difference, the surface accuracy and attitude of the main and secondary reflector surfaces need to be measured in real-time to meet the electrical performance requirements of the antenna system.However, due to the large size of the antenna and the high requirements for shape error, using traditional contact measurement methods is very difficult and inefficient, so there is an urgent need for a more advanced, efficient, and convenient measurement method to meet the needs.

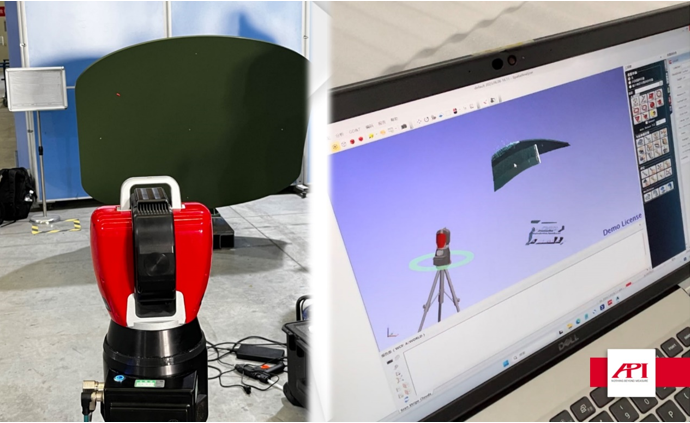

To address the challenges of large-scale, lightweight, high-precision, and high-efficiency measurement, API Company has developed the 9D LiDAR -9D LADAR (please refer to Figure 1). The working principle of the 9D LiDAR is to use optical frequency domain interferometry (OFCI) technology for non-contact high-precision spatial data collection of the target, with extremely high measurement accuracy and exceptional measurement efficiency, Simultaneously provide X, Y, Z, I, J, K, R, G, B parameters.

Figure 1: 9D LADAR

The use of 9D LiDAR for measurement has many advantages:

-The iVision intelligent vision module assists the entire system in achieving faster and more accurate feature recognition;

-Powerful programming Automation measurement and remote measurement functions;

-Embedded control system&signal processing module (no external control box required);

-Based on OFCI optical frequency domain interferometry, leading the implementation of unique ultra-high precision non-contact measurement;

-A data acquisition rate of up to 20000 points/second;

-Compact, compact, and widely used, it can be easily loaded into robots, guides, and gantry CMMs to achieve automatic measurement.

Figure 2: Application diagram of 9D LiDAR

(Upper left: near line measurement of the white body; upper right: measurement of large aircraft components and docking of cabin sections; lower left: automated measurement of large components integrated with AGV; lower right: measurement of large wind turbine blades)

Outline inspection points and measurement requirements of a small civilian antenna

1) Detect the positioning of the antenna shape relative to the support frame body;

2) Detect the shape error between the antenna shape and the theoretical parabolic surface;

9D LADAR measurement and data report

The measurement steps are briefly summarized as follows:

1) Select a stable and suitable position to fix the LiDAR and turn it on;

2) Plan the scanning path for the detection surface of the tested antenna;

3) Scan and measure the positioning holes and appearance of the antenna technology;

4) Compare the scanned process positioning hole position with the digital analog position to obtain the installation error of the profile;

5) Compare the scanned antenna shape with the theoretical parabolic surface to obtain the profile error;

Figure 3: Appearance Inspection Site of Civil Antenna Components

Overall, the installation of API LiDAR is convenient, fast, and easy to operate. Simply installing the LiDAR in a few simple steps can solve the measurement work of even large antennas, cabins, and exterior surfaces with complex structures, greatly reducing additional errors caused by instrument installation and other factors. This process fully realizes non-contact measurement, with minimal labor and time costs, Greatly improved production efficiency.

Figure 4: API Company Headquarters Building

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.