Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Two wheeled electric vehicles and design requirements

Two wheeled electric vehicles play a very important and indispensable role in modern urban transportation. Working and commuting, picking up and dropping off children, and delivering goods all reflect its characteristics of avoiding congestion, being flexible and convenient to use, and being simple and fast to operate in short distance transportation.

In the constantly increasing market demand environment, major manufacturers have higher requirements for the overall safety and fashionable design of two wheel electric vehicles, with more variable design and stricter requirements for all aspects of the processing and manufacturing of two wheel electric vehicles. So it is necessary to use more advanced processing methods to achieve the design of these shapes and the initial manufacturing of clay models.

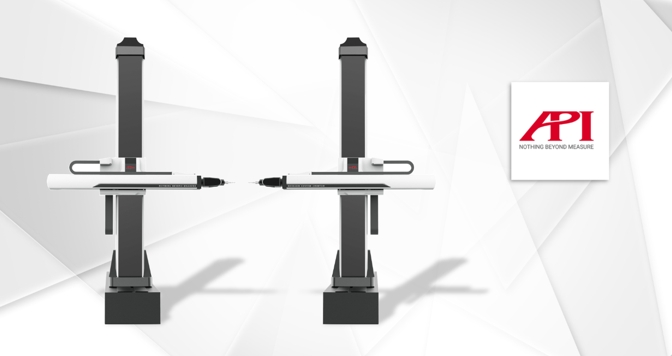

Figure 1: Galaxy Oil Mud Model Milling Machine

API Styling Design Solution

The Galaxy series oil mud model milling machine under the API brand integrates 3D measurement, marking, and milling functions, and adopts excellent industrial design concepts and manufacturing materials. Coupled with advanced software systems, it can empower and provide strong support for the molding process in many aspects of product development:

Figure 2: Milling operation for the surface modeling of the Galaxy two wheel electric vehicle oil mud model

Ensure smooth and smooth surface milling

The tactful and curved surface design often brings a sense of affinity and speed to people. Nowadays, a large number of surface elements are applied in the design of two wheel electric vehicles. The Galaxy clay model milling machine adopts 5-axis linkage processing technology to meet the large range travel of A axis ± 120 ° and B axis ± 200 °, as well as achieve 15 ″ repeated positioning accuracy, ensuring the close fitting processing of complex surfaces (the processing head swings in real-time, always along the normal direction of the processed surface), and completing the transformation of beautiful surfaces from design to reality.

In addition to providing a 5-axis linkage milling mode, Galaxy also supports a 3+2-axis machining mode with a 15 ° indexing (X, Y, Z fully automatic+A, B axis manual adjustment) to meet different user needs. (Please refer to Figure 3)

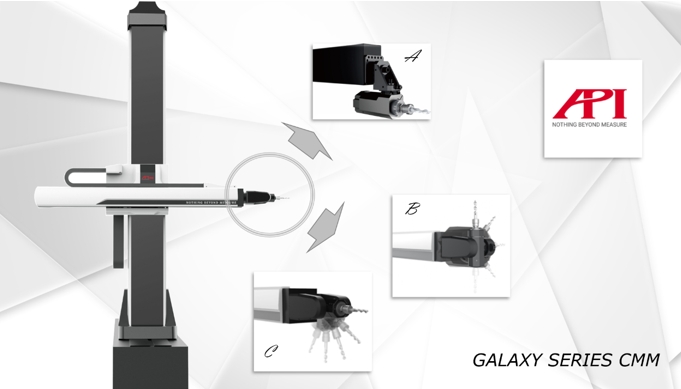

Figure 3: Galaxy milling form (A: 3+2-axis milling cutter head; B&C: 5-axis linkage fully automatic double swing angle milling cutter head)

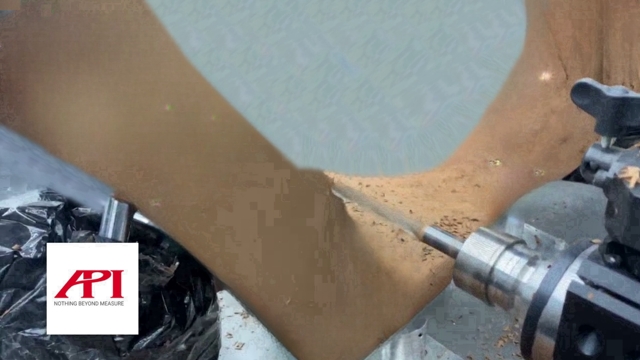

Ensure smooth processing of high-strength materials

Figure 4: Galaxy Fast Oil Mud Milling Operation

Ensure data compatibility and efficient processing

During homework, it is convenient to program digital and analog files into G code through CAM software such as UG, PRO/E, POWERMILL, etc., to quickly achieve CNC milling of various materials; The maximum operating speed is up to 20000mm/minute, combined with a spindle speed of 15000rpm, making processing convenient, efficient, and fast.

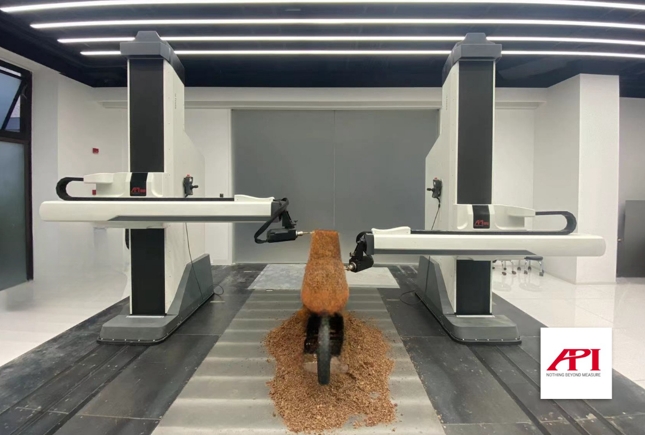

The Galaxy series oil sludge model milling machine can also be arranged in a dual machine layout, with dual machine collaborative processing, doubling the efficiency!

Figure 5: Galaxy Two Wheel Electric Vehicle Oil Mud Model in Dual Machine Collaborative Processing Operation

Ensure high compatibility with user sites

The Galaxy series adopts professional equipment appearance design, which can perfectly integrate with the design room environment, fade itself and highlight the processed model, making it easy for review.

In addition to standard dimensions, personalized customization can also be made according to the user's on-site environment to maximize integration with the user's on-site environment, while meeting functional and aesthetic needs.

Ensuring high-precision applications

Each Galaxy series milling machine that leaves the factory not only uses high-precision guide rails, gears and other components to provide high-quality hardware protection, but also adopts API patented VEC spatial error compensation technology to further optimize the 21 parameter errors of the entire machine, ensuring high-quality processing.

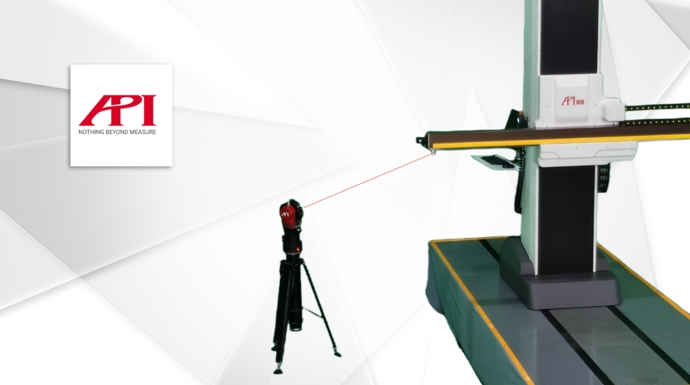

Figure 6: VEC spatial error compensation in progress

About API

The American Automated Precision Engineering Company (API) was founded in 1987 and is headquartered in Rockwell City, Maryland, USA. Since its establishment, API Company has always been committed to the research and development and production of precision measurement instruments and high-performance sensors in the field of mechanical manufacturing. Its products have been widely used in advanced manufacturing fields in the United States and countries around the world, and are in a leading position in high-precision standards for coordinate measurement and machine tool performance testing. API Company has an experienced and capable team of engineers who continuously develop advanced and innovative products to meet the needs of rapidly developing industrial technology. API Corporation is an active participant and key technology partner in many projects of the US federal government, enterprises, and scientific research. The achievements achieved so far have earned it a high reputation in the field of international precision measurement.

Figure 7: API Company Headquarters Building

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.