Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

High precision CNC machine tool&21 geometric errors

The modern manufacturing industry has put forward increasingly high requirements for the machining accuracy of CNC machine tools. By measuring the geometric errors of machine tools and compensating them, the motion performance of machine tools can be improved and the machining accuracy can be improved. Therefore, the measurement of machine tool set errors is of great significance for machine tool accuracy verification and error compensation.

Laser Interferometer is a measurement tool with high measurement accuracy, relatively complete measurement methods, and the most mature technology in machine tool error measurement. At present, domestic and foreign machine tool manufacturers are widely using laser interferometers to measure 21 geometric errors of machine tools.

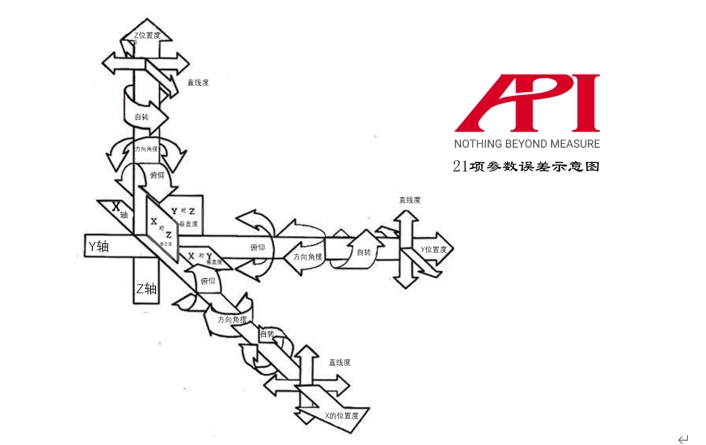

For coordinate measuring machines and three-axis machining centers, the 21 specific errors are (please refer to Figure 1):

-Three perpendicularities between the X, Y, and Z axes.

Figure 1: Schematic diagram of 21 geometric errors in machine tools

Measurement Requirements for Diagonal Lines of Machine Tool Bodies

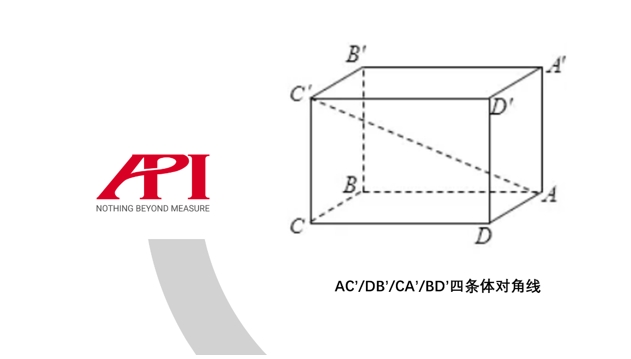

Machine tool manufacturers rarely achieve all 21 geometric error detection measurements in practical production applications. For the verification of the spatial position accuracy of machine tools, the national standard recommends a method of rapid measurement along the four body diagonals enclosed by the maximum stroke in the three directions of machine tool operation. This method can accurately reflect the geometric accuracy of the machine tool and provide theoretical guidance for spatial position error compensation.

Figure 2: Diagonal schematic diagram of machine tool body

API XD Laser Efficient Solution

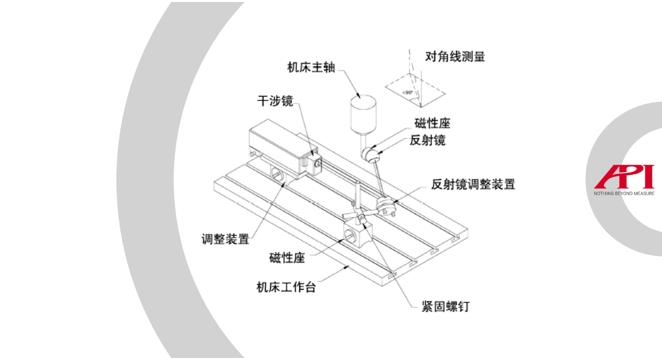

The XD Laser Interferometer from API brand has the technological advantages of high integration and precision. It is very simple and fast in measuring the diagonal position accuracy of the machine body, without the need for additional auxiliary fixtures. Simply add a spherical reflector on the basis of standard accessories to easily achieve light measurement.

Figure 3: Schematic diagram of diagonal measurement using XD Laser interferometer

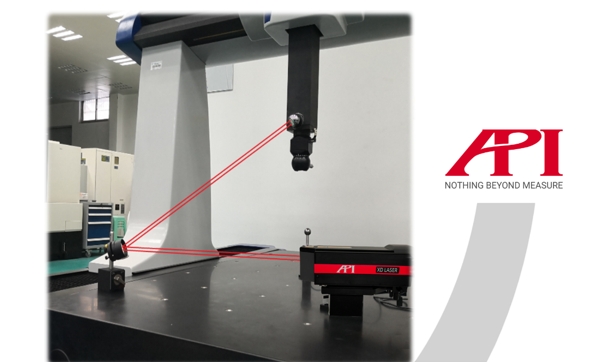

Figure 4: On site measurement of diagonal position accuracy in a coordinate system

Figure 5: Measurement site for diagonal position accuracy of CNC machine body

conclusion

Based on the technological advantages of high precision and high integration, the XD Laser series interferometer can fully meet the rapid measurement and detection of the diagonal of CNC machine tools by machine tool manufacturers and users, providing high-quality and reliable data support for production.

Figure 6: API XD Laser Interferometer

About XD Laser Interferometer

The XD Laser series laser interferometer is a patented product of API company, which is an instrument used for rapid measurement and evaluation of machine tool errors. The XD Laser series laser interferometers include 1D, 3D, 5D, and 6D models, which can be selected, configured, and upgraded according to the actual needs of users to ensure that their investments always meet their needs.

The 1D model can measure the linear positioning error of the CNC linear axis, including the diagonal position accuracy of the machine body, including positioning accuracy, repeated positioning accuracy, and reverse clearance; In addition, the movement speed and acceleration of the CNC linear axis can also be measured.

The 3D model includes all the functions of the 1D model, and can also measure the positioning straightness error of the CNC linear axis (XX direction and YY direction); After purchasing the verticality measurement accessory, you can also measure the verticality between two CNC linear axes.

The 5D model includes all the functions of the 3D model, and can also measure the deflection angle and pitch angle of the CNC linear axis; After purchasing the corresponding accessories, you can also measure the indexing accuracy error of the CNC turntable.

The 6D model includes all the functions of the 5D model, which can simultaneously measure the linear positioning error (including positioning accuracy, repeated positioning accuracy, reverse clearance), straightness (XX direction and YY direction), as well as verticality, yaw angle, and pitch angle of the CNC linear axis, while automatically measuring the rolling angle of the measured axis.

In addition, for the extremely high-precision measurement and testing needs of scientific research institutions, testing institutions, high-end manufacturing fields, etc., API also provides a selection of precision XD Laser interferometers for easy operation and excellent performance!

About API

The American Precision Engineering Corporation (API) was founded in 1987 and is headquartered in Rockwell City, Maryland, USA. Since its establishment, API Company has been committed to the research and production of precision measuring instruments and high-performance sensors in the field of mechanical manufacturing. Its products have been widely used in advanced manufacturing fields in the United States and countries around the world, and it is in a leading position in high-precision standards for coordinate measurement and machine tool performance testing. API company has an experienced and capable team of engineers,Continuously developing advanced and innovative products to meet the rapidly developing industrial technology needs. API companies are active participants and key technology partners in many projects of the US federal government, businesses, and scientific research. The achievements made so far have earned it a high reputation in the field of international precision measurement.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.